Access Requirements

Laboratories using or storing corrosive materials must have immediate access to an eyewash. Immediate access means that the eyewash is located less than 50 feet away and does not require travel through a doorway, navigation of stairs or other obstacles.

Questions about this topic can be directed here.

Testing Requirements

Research staff must test eyewashes within their laboratory space monthly, at a minimum. The American National Standards Institute (ANSI) and EHS recommends testing be done weekly.

Facility Management's (FM) Services Guide outlines services provided by FM staff: General Education Fund (GEF) funds supports the weekly testing of eyewash and shower units in public and custodial spaces by FM staff. GEF funds also support the annual testing of all units by FM staff. Non-annual testing and repair of units in lab spaces are the responsibility of the department.

Documentation

Documentation must be kept detailing when eyewashes are tested. This documentation will be checked by EHS auditors annually. Signature pages are available on the EHS website (see Documents below).

Testing Standard Operating Procedure (SOP)

To test a plumbed eyewash (for Plumbed Eyewash examples see below):

- Visually inspect the unit.

- Look for corrosion, damage to protective covers and evidence of leaks.

- Ensure the unit is clear and free of any nearby obstructions or blockage.

- If needed, assemble supplies under and/or around the eyewash to capture any outflowing water.

- Recommendations include an empty tub, 5-gallon bucket, or large trash bag.

- Activate the eyewash. The eyewash should be turned on to full strength.

- Allow the water to run long enough to ensure the flowing water is clear and free of debris. After water is clear, continue to run the water at full strength for an additional 30-60 seconds.

- Deactivate the eyewash. Collected water may be poured down a sink drain. Clean up any water that may have splattered or spilled onto the floor and/or wall.

- Replace protective caps, if present.

- If repairs are needed, submit a work request to the FM Work Control Center through FM@YourService. Examples include:

- Water flow uneven, too strong or too weak.

- Water too hot or too cold. Water temperature should be between 60° and 100° F.

- Water does not run clear.

- Sign the testing record with your initials, or signature, and the date.

To test a non-plumbed, self-contained eyewash (for Self-Contained Eyewash examples see below):

- Visually inspect the unit.

- Look for corrosion, damage to protective covers and evidence of leaks.

- Ensure the unit is clear and free of any nearby obstructions or blockage.

- If needed, replace or replenish the flushing fluid in the reservoir.

- Flushing fluids, typically buffered saline solutions, have expiration dates. Replace the flushing fluid per the expiration date. If no expiration date is supplied by the manufacturer, replace at least yearly.

- Follow any other manufacturer instructions if necessary.

- Sign the testing record with your initials, or signature, and the date.

Compliant Eyewash Types

Any eyewash installed on campus should meet the requirements of ANSI Z358.1-2014. New departmental installations in lab spaces are the responsibility of the department.

Plumbed Eyewashes

Wall -Mounted - A plumbed eyewash that is mounted on the wall. The eyewash may or may not have a bowl. The eyewash may drain to the building plumbing or to the floor.

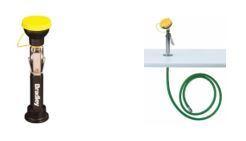

Floor-Mounted - A plumbed eyewash that is mounted from the floor; also known as a pedestal. The eyewash may drain to the building plumbing or to the floor.

Deck Mounted

Swing Arm - A plumbed eyewash that is mounted on a countertop, usually next to a sink. The eyewash remains over the countertop when not in use. For use, the eyewash swings over the sink basin and drains directly into the building plumbing through the sink drain.

Dual-Head Drench Hose - A plumbed eyewash that is mounted on a countertop, usually next to a sink. The handle is attached to a flexible hose below the countertop. The eyewash can be used in place or pulled out for closer use. If used over a sink, it drains directly into the building plumbing through the sink drain.

Faucet-Mounted - A plumbed eyewash that is mounted directly on a faucet. The eyewash drains directly into the building plumbing through the sink drain. Labs must contact the EHS Chemical Hygiene Officer before installing these units.

Note: Faucet-mounted eyewashes are often not temperature-controlled nor can be activated in one second or less. If it does not meet all eyewash performance and installation requirements then it is considered a supplemental device only.

Self-contained Eyewash - A non-plumbed eyewash that has a reservoir of flushing fluid and uses gravity to feed that fluid to the eyewash heads. Usually mounted on a wall. Self-contained units must be able to provide 0.4 GPM tepid flushing fluid for 15 minutes to qualify as a OSHA-compliant eyewash.

Supplemental Personal Eyewash Types

The devices below are not OSHA-compliant eyewashes; they may only be used as supplemental units. These units may not be used as a permanent eyewash and therefore must be replaced by an OSHA-compliant eyewash as soon as possible.

Deck-Mounted Single-Head Drench Hose - Like a dual-head drench hose, a plumbed device that is mounted on a countertop, usually next to a sink, and attached to a flexible hose below the countertop. If used over a sink, it drains directly into the building plumbing through the sink drain.

Squeeze Bottle - A plastic bottle usually filled with a buffered saline solution. Saline solutions expire and should be changed out according to the schedule recommended by the manufacturer. If tap water is used in a squeeze bottle, the water should be changed weekly.

Document:

Eyewash Station Monthly Flush Check

Eyewash Station Weekly Flush Check