- Purpose

- Applicability

- Potential Risk

- Injury and Illness Prevention

- Training

- Personal Protective Equipment (PPE)

- First Aid, Medical Attention, and Treatment

- Additional Safe Handling Information for Specific Activities Involving Glassware

- Acknowledgement

- Appendix

Purpose

The purpose of this research safety guidance is to prevent and/or minimize broken glass injuries while handling laboratory glassware through:

- awareness of personal protective measures, including the use of slip-resistant and cut-resistant gloves while handling glassware;

- safe disposal of both broken and unbroken glassware, pipettes and vials, etc., in sharps container to prevent injury to those handling waste containers; and

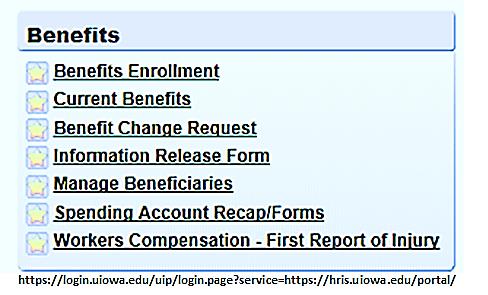

- the online submission of the First Report of Injury (FROI) form for reporting injuries; this facilitates compliance reporting as well as follow-up evaluations and corrective actions to prevent future incidents.

Applicability

This guidance applies to all research and teaching labs, manufacturing units, and staff and students who handle glassware in lab experiments, e.g., making media, reagent preparation, synthesis, analysis, vacuum techniques, and glassware cleaning. Additional site specific procedures may be incorporated to meet the needs of individual work areas, core facilities, process labs, and manufacturing units in the university.

Potential Risk

Warning

- Broken glass and other sharps are physical hazards.

- Broken glass also has the potential to be a health hazard if it is contaminated with toxic chemicals, blood, or infectious substances which may enter the body through a cut or puncture.

Broken glass penetrates the skin and causes lacerations just like sharp, needles, and razors.

The most likely person to be injured from mishandling of glassware is the user. However, anyone in the vicinity of imploding glass is likely to be hurt, so it is important for everyone to wear their personal protective equipment (PPE). The probability of being injured by broken or breaking glass is ‘LIKELY’ and the potential severity of injury from a pressurized or vacuum glass apparatus incident is ‘SEVERE TO EXTREME.’ By implementing safety controls and using PPE, the potential risks associated with glassware handling can be reduced. Please see the table below.

‘LIKELY’ and the potential severity of injury from a pressurized or vacuum glass apparatus incident is ‘SEVERE TO EXTREME.’ By implementing safety controls and using PPE, the potential risks associated with glassware handling can be reduced. Please see the table below.

Specialized glassware, including Schlenk line tubes, separatory funnels, vials, desiccators, autoclavable tubing/glassware, micro-fabrication and thin film deposition devices, laser optics, etc., are prone to breakage from hairline cracks and from dropping the item. Wear slip-resistant or cut-resistant gloves when handling glass to prevent cuts, abrasions, and skin puncture.

| Type of Glassware Injury |

Safety Control Recommendations for Risk Reduction |

Example Process/Activities | Potential Risk |

|

Injury from imploding glass or flying glass. |

Consider other factors that could possibly reduce risks, such as: Use low intensity vacuum devices, use smaller flasks, assure vacuum is released at the vacuum pump before removing vacuum flask/glassware, and make sure glassware under vacuum is not located where it could be bumped or struck. |

Working with vacuum apparatus. | HIGH |

| Cuts when forcing glass tubing or pipettes onto rubber stoppers |

|

Working with glass tubes or Pasteur pipettes. | Moderate Plus |

| Cuts caused by breaking inlet/outlet stems from reflux condensers or desiccator stems |

|

Assembling/disassembling condensers, or holding the stem to open or close desiccators. | Moderate |

| Chemical or other hazardous material exposure caused by sharps injuries from contaminated glassware |

|

Working with or transferring toxic chemicals in reaction flasks, separatory funnels, etc. | Moderate |

| Broken or breaking glass during laboratory work/process (Injury from slipping glass) |

|

Washing lab glassware, transporting to or from drying ovens, autoclaves, etc. | Low |

| Breaking glass ampules | Use ampoule breakers or triangular file to score the glass as appropriate. | Working with pharmaceutical and analytical standards or other sealed chemical ampoules. | Low |

| Inserting the inlet of an auto-pipetting device onto a glass pipette |

|

Dispensing liquid reagents in labs. | Low |

| Cutting glass tubes |

|

Preparing aspirator/vacuum flasks filtration equipment | Low |

Injury and Illness Prevention

- Inspect glassware for defects or cracks before use.

- Do not handle broken glass with bare hands. Use appropriate cut-resistant gloves to handle broken glass.

- Use forceps, tongs, scoops, or other mechanical devices for removing or retrieving broken glass from the work area or a fume hood.

- A dustpan and brush should be used to clean up shards/small pieces of broken glass, Pasteur pipettes, or shards of glass.

- Do not remove any items from a sharps container.

- Substitute glassware with plastic ware, including desiccators, wherever possible.

Training

The principal investigator (PI) or laboratory supervisor is responsible for providing the most appropriate training on safe handling of glassware to their staff and students. The PI or laboratory supervisor is also responsible for conducting an equipment-specific and process-specific risk assessment and implementing safe work practices to minimize injuries due to broken glass.

- All lab staff using glassware and other sharps should receive training in safe handling and disposal of sharps.

- Researchers should consult with their supervisor prior to introducing any new processes in their research lab.

- Researchers should exercise caution while handling and transporting glassware.

- Researchers are responsible for wearing appropriate PPE during the cleanup and disposal of broken glassware.

- Researchers should read and follow the manufacturer's instructions when assembling specialized glass apparatus and equipment that potentially contains sharps (e.g. autoclaves, automated dishwashers, microtome tissue slicers, etc.).

Personal Protective Equipment (PPE)

Equipment-specific safety precautions should be followed to prevent broken glass injuries by selecting and using proper PPE. Process-specific PPE may include cut-resistant gloves, full length lab coats/gowns, and a face shield/safety goggles. These provide protection of the skin, including forearms, fingers, and the eyes. All research labs should have cut/puncture-resistant gloves similar to Kevlar® or D-Flex® and an approved sharps disposal container large enough to contain broken glass.

First Aid, Medical Attention, and Treatment

A tetanus shot is strongly encouraged for laboratory researchers who handle glassware activities such as cleaning and removal of glassware from hot ovens or autoclaves, etc. In the event of an injury involving a broken glass or sharp instrument, the following steps should be followed:

- Encourage bleeding of the wound; but do not directly massage or attempt other forceful means to remove any remaining broken glass from the wound.

- Wash the wound thoroughly with warm water and soap if available. Use cold water if warm water is not available.

- Seek medical attention as appropriate. Detailed emergency information is available at the EHS web site for medical attention and emergency treatment.

- Immediately report the incident to the PI or lab supervisor, as all injuries from lab incidents exposures and near miss incidents should be reported to these individuals.

- If the incident involves potential exposure to infectious materials, then immediate medical attention is required. In situations where the risk of exposure to infectious materials is unknown or uncertain, and the injury occurred in a biological research area, the injury should be treated as a possible exposure to infectious material and reported immediately to the Associate Biological Safety Officer (353-5679) or contact EHS at 335-8501, so a risk assessment can be initiated.

- Paid students, staff and faculty should complete FROI online within 24 hours of the incident or as soon as possible. If the individual is unable to complete the FROI right away, the supervisor can complete one for him/her.

Additional Safe Handling Information for Specific Activities Involving Glassware

Specific activities involving glassware are discussed in Appendix A. These include working with, handling, or procedures involving the following:

- Schlenk line apparatus

- Vacuum glass apparatus

- Autoclaving glassware

- Glass thermometers

- Washing/cleaning glassware

Acknowledgement

Special thanks to Professor Laurence Fuortes for reviewing the draft document.

Appendix A

Additional Safe Handling Information for Specific Activities Involving Glassware

Schlenk line Apparatus

Warning

- A mixture containing condensed liquid air/oxygen and organic compounds in a liquid nitrogen trap can potentially result in an explosion.

- Contents of a liquid nitrogen trap should be promptly emptied after each experiment.

- If the vacuum line valve is kept closed after the experiment, condensed liquid air in the liquid nitrogen trap will evaporate to a gas phase at ambient temperature and the trap will become a pressurized glass tube and can lead to a potential explosion.

- The fume hood sash should be closed to the lowest possible height to prevent glass flying out of the fume hood in the event of an explosion/implosion.

The Schlenk line is a specialized glass apparatus consisting of a vacuum pump, inert gas connection, liquid nitrogen cryotrap and paraffin oil gas bubbler and is typically used for manipulating air/moisture sensitive compounds. Researchers should be individually trained in Schlenk line manipulation under the direct supervision of the principal investigator or an experienced senior researcher.

High vacuum is often applied to remove the last traces of solvent from a sample. Implosion can occur due to the use of a high vacuum and flaws in glass apparatus. Therefore, researchers should check for cracks in glassware before starting work using a Schlenk line. They should also check for the presence of condensed liquid air (oxygen condensation) in the cryotrap before starting a Schlenk line work because this condition may lead to explosions. If needed, the vacuum trap valve should be opened to dissipate cryotrapped oxygen (light blue color).

Exposure to chemicals and glassware injuries while preparing or using the Schlenk line can be minimized by setting up Schlenk lines in a fume hood and proper planning, including performing a hazard evaluation prior to work.

Vacuum Glass Apparatus

Vacuum glassware with volumes of one or more liters should be wrapped with friction tape, electrical tape, or a plastic mesh cage to restrain fragments in the event of an implosion. This is appropriate for safe handling of vacuum storage bulbs, rotary evaporators, vacuum desiccators, etc. Round-bottomed thick-walled Pyrex or borosilicate glassware should be used for vacuum operations.

Autoclaves

All glassware should be inspected prior to autoclaving. Older glassware can be less stable and may break during the process. Wear insulated thermal gloves when removing glassware from autoclaves. If broken glass is discovered, the autoclave should be left to cool completely before cleaning broken glass debris. The OSHA fact sheet publication on Autoclaves and Sterilizers describes the DO’s and DON’Ts while working with autoclaves and Sterilizers. Assure that employees using the autoclave have been informed how to use autoclaves safely

Thermometers

- Whenever possible, replace glass thermometers with temperature probes or mercury-free alcohol-filled thermometers.

- If a mercury thermometer or monometer is used in specialized applications, it is highly recommended to coat these devices with PTFE resin.

- Do not use a thermometer as a stirring rod.

- Make sure the measuring range of the thermometer is appropriate to minimize breakage from overheating the thermometer.

- If thermometers are to be inserted into a rubber stopper, a tight fit can be accomplished using a PTFE tape as a sleeve. For distillation or reflux experiments with air/moisture sensitive reagents, thermometers with a ‘ground-glass joint’ is highly recommended.

Washing/Cleaning Lab Glassware

- Protective eyewear such as a face shield, safety goggles or safety glasses with side shields should be worn to protect against splatter from cleaning agents or from flying glass shards.

- When cleaning, handle glassware carefully, as the soap and water will make the glassware slippery.

Researchers should wear thick water-resistant rubber or neoprene gloves to protect hands against chemicals such as acids, alkalis, solvents, and detergents used during glassware cleaning operations. Gloves with textured/slip-resistant palms or cut-resistant inner gloves are recommended.

Unbroken/Broken Glassware Disposal

- NEVER dispose of contaminated glassware, including broken culture tubes and flasks, in a cardboard box.

- Broken glass from research laboratories must be discarded in a sharps container. .

Please see EHS Waste Management Manual – Appendix XI – Sharps Management Chart for Complete Information for EHS disposal procedures for glassware, plastic-ware and other sharps.